Exhibition Gallery

Exhibition Gallery

Microbes—tiny organisms too small to be seen with the naked eye—have altered human history.

Life forms such as bacteria, yeasts, and molds can cause sickness or restore health, and help produce foods and beverages.

Scientists, in partnership with industry, have developed techniques to harness the powers of these microbes. In recent years, headline—grabbing technologies have used genetically modified bacteria to manufacture new medicines.

A glimpse into the past reveals a history of human enterprise that has adapted these tiny organisms for health and profit. This exhibition explores some of the processes, problems, and potential inherent in technologies that use life.

Microbes—tiny organisms too small to be seen with the naked eye—have altered human history.

Life forms such as bacteria, yeasts, and molds can cause sickness or restore health, and help produce foods and beverages.

Scientists, in partnership with industry, have developed techniques to harness the powers of these microbes. In recent years, headline—grabbing technologies have used genetically modified bacteria to manufacture new medicines.

A glimpse into the past reveals a history of human enterprise that has adapted these tiny organisms for health and profit. This exhibition explores some of the processes, problems, and potential inherent in technologies that use life.

Half-Hours with the Microscope, Edwin Lankester, MD, illustrated by Tuffen West, 1860

Courtesy National Library of Medicine

Tinkering with DNA

All organisms, from microbes to humans, are governed by the genetic code embedded in their DNA. In the 1970s, scientists inserted a human gene into the genetic material of a common bacterium. This so—called "recombinant" microorganism could produce the protein encoded by the human gene.

Eager to explore the potential of this recombinant DNA technique, investors joined forces with research scientists to develop industrial applications. Two of the earliest products to reach the market were human insulin, used to treat diabetes, and human growth hormone, used in children with pituitary gland disorders.

Recombinant technology provided a commercially viable way to make proteins for medical use and gave rise to a new industry—dubbed "biotech."

Top: E.coli bacteria exchanging genes

Courtesy of Charles C. Brinton Jr.

Bottom: Views of E. coli bacteria by scanning electron microscope

Courtesy of David Scharf Photography

Escherichia coli (E. coli) bacteria are the workhorses of recombinant DNA technology. The ability of bacteria to easily exchange and absorb new pieces of DNA made them good vehicles for genetic engineering techniques.

-

Copy Link

Copied

Protropin, human growth hormone, 1987

Courtesy National Museum of American History

The Food and Drug Administration approved Protropin, human growth hormone made using genetically modified bacteria, for therapeutic use in 1985.

-

MedlinePlus

-

Copy Link

Copied

“First Man-made Protein in History,” LIFE, May 8, 1964

Courtesy © 1964 Time Inc. Reprinted with permission. All rights reserved. Image by Fritz Goro. ©Time Inc. Used with permission. All rights reserved.

In this illustration the sequences of colored balls represent the steps in a complex chemical process for building insulin molecules. Although this achievement was important for research, the process was not feasible for commercial insulin production.

-

MedlinePlus

-

Copy Link

Copied

“Ribbon Diagram” of human growth hormone, 2013

Courtesy National Center of Biotechnology Information (NCBI)

Ribbon diagrams are a graphic tool that helps researchers to visualize protein structures such as growth hormone. Understanding the relationship between DNA, genes, and protein structures led to the birth of genetic technologies including recombinant DNA.

In 1988, the National Center for Biotechnology Information was established at the National Library of Medicine to provide a central source for genetic and molecular data, including the gene sequences and structures of the proteins essential to human health.

-

Copy Link

Copied

Harvesting Hormones

Hormones are complex molecules that regulate vital functions, including growth and development. In humans and animals, hormones are produced in glands and organs such as the pituitary, thyroid, and pancreas.

Before recombinant DNA technology, drug manufacturers extracted hormones, including insulin and growth hormone, directly from animal or human glands. Human growth hormone (hGH) required a supply of pituitary glands from human cadavers that was difficult to obtain.

The new technology ensured an abundant supply of these drugs. In the case of hGH, the number of children requiring it to treat pituitary gland disorders is quite small. However, with the supply secure new markets and applications emerged. The drug is used to increase height in otherwise healthy children, to enhance athletic performance, and to rejuvenate aging bodies.

“The position of the pituitary gland within the skull,” from The Pituitary Gland: Clinical Application of its Hormone Factors, Armour Laboratories, 1940s

Courtesy National Library of Medicine

The pituitary gland, the size of a chickpea, situated in the center of the brain, secretes nine different hormones, one of which regulates human growth.

-

MedlinePlus

-

Copy Link

Copied

“How HGH Made One Dwarf Tall” LIFE, October 14, 1966

Courtesy © 1966 Time Inc. Reprinted with permission. All rights reserved. Images courtesy Royal Canadian Air Force.

A young man featured in Life magazine in 1966 gained 15 inches with the help of growth hormone injections. Although the extracted hormone was available for therapeutic use by the late 1950s, its availability was severely restricted by the limited supply of human glands.

-

MedlinePlus

-

Copy Link

Copied

“The Steer” from Armour’s Endocrine and Other Organotherapeutic Preparations, 1940s

Courtesy National Museum of American History

Diagram of glands and organs used for making pharmaceutical preparations.

-

MedlinePlus

-

Copy Link

Copied

Insulin plasmid tubes, 1970s

Courtesy National Museum of American History

These tubes contained samples of bacterial DNA which had been genetically modified to contain the human insulin gene. Researchers used the DNA in the original experiments to produce human insulin from recombinant bacteria.

-

MedlinePlus

-

Copy Link

Copied

Pituitary gland products, 1910s–1950s

Courtesy National Museum of American History

These bottles contain medicines made from the pituitary glands of cattle. Although these tablets and powders were widely available, they were not effective. Any hormones present were destroyed by the human digestive system before they could work. In the 1940s, researchers isolated pure growth hormone from cattle glands. This hormone could be injected, but due to differences between species, bovine hormone was not effective for human use.

-

MedlinePlus

-

Copy Link

Copied

Grow Young with HGH by Dr. Ronald Klatz, 1998

Courtesy Harper Collins and National Museum of American History

-

MedlinePlus

-

Copy Link

Copied

“My Little Brother on Drugs,” by Jenny Everett, Popular Science, April 2004

Used with permission of Popular Science Copyright ©2013. All rights reserved.

-

MedlinePlus

-

Copy Link

Copied

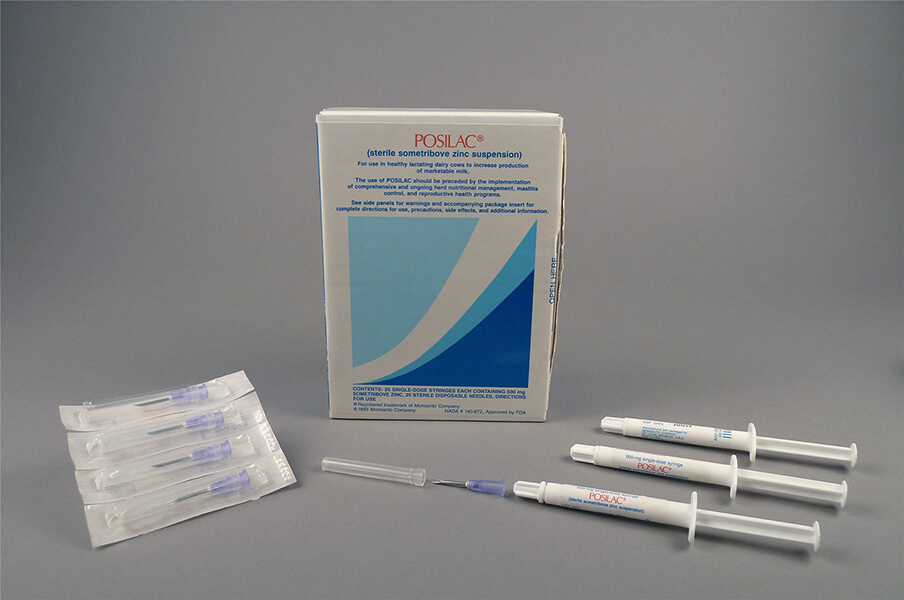

Posilac, recombinant bovine growth hormone, Monsanto Company, 1994

Courtesy National Museum of American History

Following the success of human growth hormone (hGH), researchers developed a recombinant bovine (cow) growth hormone, which became available in 1994. The drug did not treat a disorder in cattle, but instead drug companies marketed the substance to dairy farmers to increase milk production.

-

DigitalCollections

-

MedlinePlus

-

Copy Link

Copied

Making Yellow Magic

Microbes are equipped with defense mechanisms to help ensure their survival. Penicillium, the bluish-green mold that grows on stale food, produces a substance that has the power to kill its bacterial competition. Many of these bacteria are also deadly to humans.

In the years leading into World War II, British scientists established the life-saving potential of Penicillium's natural antibiotic. Prompted by the war emergency, the United States government teamed with drug companies to mass-produce penicillin. The ability of the drug to prevent fatal infections among the wounded inspired the nickname "yellow magic."

The anti-infective power of penicillin and other antibiotics has led to their overuse in medicine and agriculture, resulting in the emergence of drug-resistant bacteria that threaten human health.

“The Era of Antibiotics,” painted by Robert A. Thom for Parke, Davis & Company, 1950s

Printed with Permission of American Pharmacists Association Foundation. Copyright 2009 APhA Foundation.

Penicillin research and production are depicted in this painting by Robert A. Thom, commissioned by Parke, Davis & Company as part of their “Great Moments in Pharmacy” advertising campaign in the 1950s.

-

MedlinePlus

-

Copy Link

Copied

“Thanks to Penicillin…He Will Come Home!” penicillin advertisement, Schenley Laboratories, 1944

Courtesy Schenley Laboratories, Inc.

Advertising played a role in establishing the image of penicillin as the wonder drug.

-

MedlinePlus

-

Copy Link

Copied

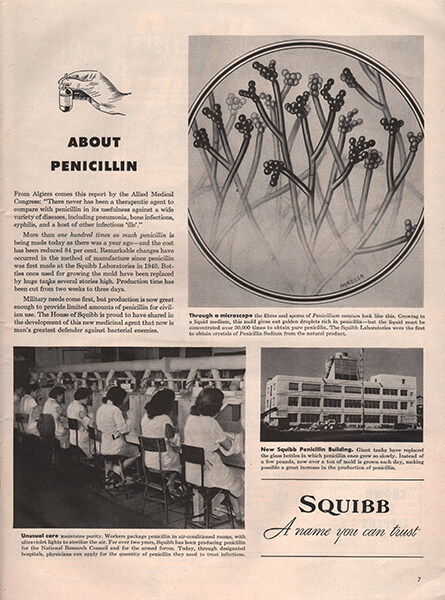

“Fibres and spores of Penicillium notatum” papenicillin advertisement, Squibb Laboratories, 1944

Courtesy National Museum of American History

“Growing in a liquid medium, this mold gives out golden droplets rich in penicillin—but the liquid must be concentrated over 30,000 times to obtain pure penicillin.”

-

MedlinePlus

-

Copy Link

Copied

Penicillin manufacture at Oxford University, early 1940s

Courtesy Sir William Dunn School of Pathology, Oxford University

Six “Penicillin Girls” nurtured the growing mold and harvested the penicillin from the hundreds of culture vessels at the manufacturing operation established at Oxford University in 1940.

-

MedlinePlus

-

Copy Link

Copied

Penicillin culture vessel, 1940

Courtesy National Museum of American History

-

MedlinePlus

-

Copy Link

Copied

Penicillin products from American manufacturers, 1940s

Courtesy National Museum of American History

Unable to establish large–scale commercial production, the British turned to the United States in 1942. More than twenty American drug companies joined the U.S. government’s penicillin production effort. Industrial fermentation tanks replaced small vessel production and by 1944 penicillin supplies met military needs.

-

MedlinePlus

-

Copy Link

Copied

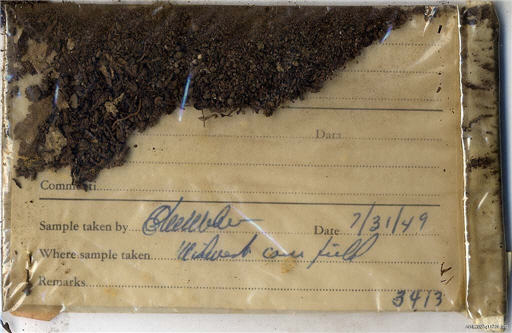

Soil sample, Charles Pfizer and Company, 1949

Courtesy National Museum of American History

Soil, naturally rich in microbial life, became an important source for antibiotic discovery. The Pfizer company alone tested over 100,000 soil samples from around the world, as drug companies competed to develop new products. This envelope of soil, from a cornfield in the Midwest, yielded a winning microbe and led to a successful new antibiotic named Terramycin.

-

MedlinePlus

-

Copy Link

Copied

“A handful of earth that may save your life“ penicillin advertisement, Parke, Davis & Company, 1962 Copyright © Pfizer Inc. All rights reserved.

The Parke Davis company tested thousands of soil samples each year for new microorganisms. Advertisements in popular magazines highlighted the enormous research effort required to produce one or two useful products.

-

MedlinePlus

-

Copy Link

Copied

Polycillin oral antibiotic, Bristol–Myers Company, 1977

Courtesy National Museum of American History

New penicillins, such as ampicillin (brand name Polycillin) developed in the 1960s, were effective for treating many common infections. Oral formulas made taking the medicine more convenient. Doctors and patients came to rely on antibiotics even in uncertain diagnoses.

-

MedlinePlus

-

Copy Link

Copied

Yellow Magic: The Story of Penicillin, by J. D. Ratcliff, 1945

Courtesy Random House

“Pig’s Progress” LIFE, December 3, 1951

Courtesy © 1951 Time Inc. Reprinted with permission. All rights reserved. Image by Albert Fenn. ©Time Inc. Used with permission. All rights reserved.

A piglet thrives on a formula of artificial milk and Terramycin, an antibiotic, developed to accelerate growth in animals.

-

MedlinePlus

-

Copy Link

Copied

“How Meat Serves Everybody!“ Life, November 14, 1949

Courtesy National Museum of American History

Meat production and consumption expanded rapidly along with the prospering American economy in the years following World War II. This advertisement from the American Meat Institute emphasizes the benefits of meat for human health, the economy, and soil conservation.

-

MedlinePlus

-

Copy Link

Copied

Living Factories

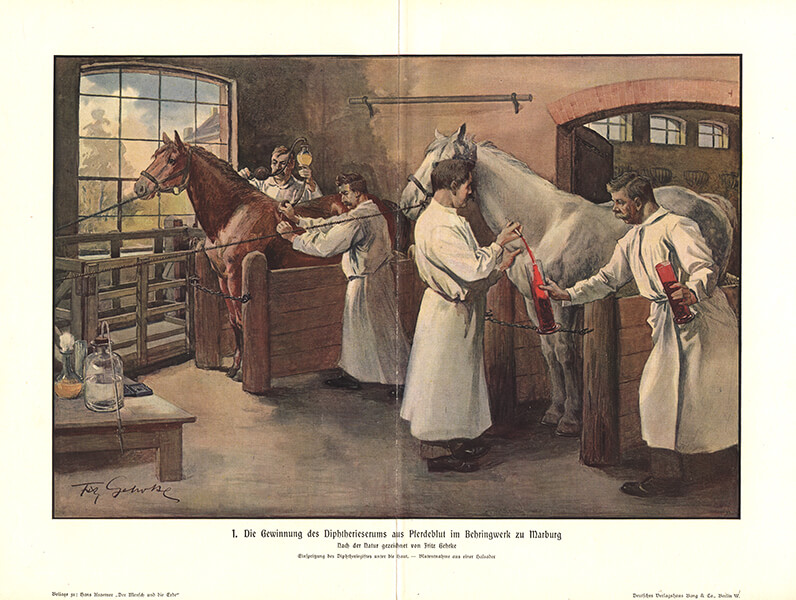

Humans and animals have natural defense systems that produce antibodies in the blood to combat bacteria and other harmful substances invading the body. In the late nineteenth century, scientists investigating this immune response in animals developed new methods for treating diseases in humans.

One of these early therapies used blood serum, collected from animals inoculated with toxins from bacteria. The natural protection these animals developed against the toxin could be passed to humans through injections of the serum. In commercial production, horses and other large animals served as living serum factories to grow the so—called "antitoxins" for human use.

Serum therapy provided an effective cure for diphtheria, an often fatal childhood disease. The demand for serum established a new drug industry that required the use of large numbers of animals for production.

Recovering the diphtheria serum from horse blood in Marburg, Germany, drawn from nature by Fritz Gehrke, 1890s

Courtesy of National Library of Medicine

-

MedlinePlus

-

Copy Link

Copied

Guinea pigs used for testing serums and toxins at Parke Davis & Company, ca. 1925

Courtesy National Museum of American History

-

MedlinePlus

-

Copy Link

Copied

Guinea pig room at Parke Davis & Company, ca. 1925

Courtesy National Museum of American History

-

MedlinePlus

-

Copy Link

Copied

“Penicillin Issue” cover of Journal of the American Pharmaceutical Association, April 1945

Courtesy National Museum of American History

Injecting diphtheria antitoxin, 1895

Courtesy The Historical Medical Library of The College of Physicians of Philadelphia

-

MedlinePlus

-

Copy Link

Copied

“How New York City’s Health Department Makes Serums and Vaccines for the United States Army?” Popular Science, December 1917

Courtesy Smithsonian Libraries, The National Museum of American History Library

-

MedlinePlus

-

Copy Link

Copied

“The Voges holder for guinea–pigs” from The Principles of Bacteriology by Alexander Crever Abbott, 1899

Courtesy National Museum of American History

This tube was used to immobilize guinea pigs during inoculations. Injections of toxins and serums were administered through the cut–out window. Although their role was less publicized, small mammals, such as the guinea pig, were essential to the serum manufacturing process.

-

MedlinePlus

-

Copy Link

Copied

Guinea pig holder, early 20th century

Courtesy National Museum of American History

-

MedlinePlus

-

Copy Link

Copied

Animal Record Card from Hygienic Laboratory Bulletin No. 21, 1905

Courtesy National Library of Medicine

Animal Record Card for a guinea pig used in serum and toxin testing. Pig No. 1567 is identified by a rough sketch of its color markings.

-

MedlinePlus

-

Copy Link

Copied

Harness and lead for the horse “First Flight” and a bottle of botulism antitoxin, 1970s

Courtesy National Museum of American History

The thoroughbred horse “First Flight” was used to produce serum for botulinum toxin, the deadly bacterial poison often spread through foods. He produced the antitoxin for the U.S. Army from 1978–1993.

-

MedlinePlus

-

Copy Link

Copied

A photo of Old Faithful in Who’s Who Among the Microbes by William H. Park and Anne W. Williams, 1929

Courtesy National Library of Medicine

“Old Faithful,” was a horse that produced antitoxins for the city of New York in the early twentieth century. A few of the individual horses used for serum production were celebrated for their service to humankind.

-

MedlinePlus

-

Copy Link

Copied

Animal record book, New York City Department of Health, 1897–1898

Courtesy National Museum of American History

-

MedlinePlus

-

Copy Link

Copied

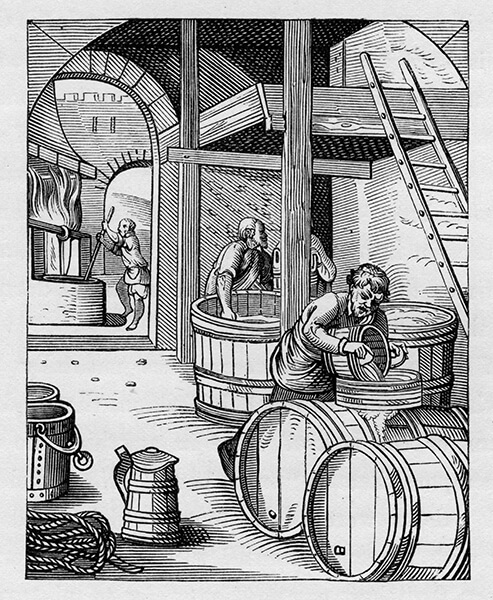

Brewing Mysteries

Beer making is an old technology that relies on microorganisms. Brewers, however, barely knew of the existence of microbes, much less the critical role they played in their livelihood. Problems encountered in beer production, motivated scientists to study the secrets of this "invisible world."

In the mid—19th century, chemist Louis Pasteur worked with French beer makers to discover what was causing their product to spoil. Through his investigation into the "diseases" of beer, Pasteur demonstrated the essential role that yeast, a tiny living organism, played in the fermentation process and identified microorganisms that caused beer to go bad.

Breweries, as well as other fermentation based industries, adopted new scientific tools and techniques in order to better control the productive and destructive power of microorganisms.

Engraving of a beer vat designed by Louis Pasteur, ca. 1880

Courtesy National Library of Medicine

The closed fermentation tank prevented air–borne bacteria from entering and spoiling the brew.

-

Copy Link

Copied

“The Brewer,” engraving by Jost Amman, 16th century

Courtesy National Museum of American History

-

Copy Link

Copied

Drawings by Louis Pasteur of microscopic organisms, culturing vessels and equipment from his experiments, 1861

Courtesy Library of Congress

-

Copy Link

Copied

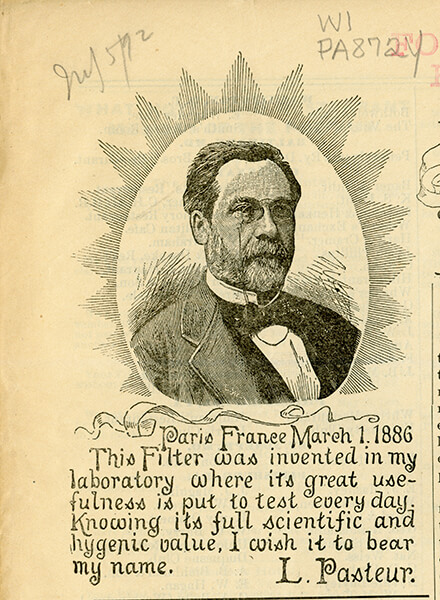

French chemist Louis Pasteur, 1889

Courtesy National Library of Medicine

Pasteur’s work is celebrated as laying the foundation for the science of bacteriology. His investigations on the behalf of French industry established tools and techniques necessary for controlling the productive and destructive power of microorganisms.

-

Copy Link

Copied

Pasteur Chamberland filter, early 20th century

Courtesy National Museum of American History

-

Copy Link

Copied

“Section and elevation of Chamberland’s filter” from Microbes, Ferments and Moulds, Edouard Louis Trouessart, 1891

Courtesy National Library of Medicine

-

Copy Link

Copied

Pasteur flask, early 20th century and Microscope, made in France by Nachet et Fils, ca. 1860

Pasteur used special tools and methods for studying the activity of microorganisms in the brewing process. Flasks with long curved necks allowed oxygen to get in while keeping unwanted microbes out. Improvements in microscope lenses made the identification of different microorganisms possible.

-

Copy Link

Copied

Yeast, Études sur la Bière (Studies on Beer) by Louis Pasteur, 1876

Courtesy National Library of Medicine

An illustration in Pasteur’s book shows what healthy and worn–out yeast cells look like when viewed through the microscope.

-

Copy Link

Copied

Diagram and cross-section of beer vat, Études sur la Bière (Studies on Beer) by Louis Pasteur, 1876

Courtesy National Library of Medicine

-

Copy Link

Copied

Prepared culture tubes and sterile swab, Parke, Davis & Company, 1898

Courtesy National Museum of American History

These culture tubes were used to grow microbes for identification. They contain a special preparation of nutrients in a jelly–like base. A sterile instrument like the swab was used to transfer the test substance to the tube.

-

Copy Link

Copied

“Bacterium Acidi lactici,” Atlas of Bacteriology, 1897 Courtesy National Library of Medicine

Lactic–acid bacteria, a major cause of spoilage in the brewing process, are shown growing on a variety of culture media.

-

Copy Link

Copied

“Incubator,” from The American Handbook of the Brewing, Malting and Auxiliary Trades by Robert Wahl, PhD, and Max Henius, PhD, 1901

Courtesy National Museum of American History

Brewing handbooks described the tools and techniques needed for the study of yeasts and bacteria encountered in the brewing process.

-

Copy Link

Copied

Terramycin products, Charles Pfizer and Company, early 1960s

Courtesy National Museum of American History

Drawing of Yeast by Anton van Leeuwenhoek, 1680

Courtesy National Library of Medicine

Dutch lens maker Anton van Leeuwenhoek was probably the first person to see yeast. He made this drawing in 1680, after viewing beer through his primitive homemade microscope.

-

Copy Link

Copied

“How did they ferment beer?”

Created by Link Studio

-

Copy Link

Copied

Introduction

1 of 14

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

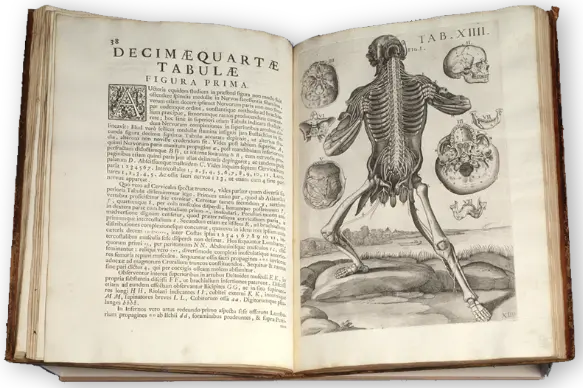

- Anatomist |Govard Bidloo (1649–1713)

- Type |Copperplate engraving with etching

Egestas purus viverra accumsan in nisl. Vulputate dignissim suspendisse in est ante in nibh mauris cursus. Consectetur purus ut faucibus pulvinar elementum integer enim neque volutpat. Massa sapien faucibus et molestie ac feugiat sed lectus vestibulum. Id diam vel quam elementum pulvinar etiam. Tristique sollicitudin nibh sit amet commodo nulla facilisi. Odio euismod lacinia at quis risus sed vulputate odio.