Exhibition Gallery

Exhibition Gallery

Microbes—tiny organisms too small to be seen with the naked eye—have altered human history.

Life forms such as bacteria, yeasts, and molds can cause sickness or restore health, and help produce foods and beverages.

Scientists, in partnership with industry, have developed techniques to harness the powers of these microbes. In recent years, headline—grabbing technologies have used genetically modified bacteria to manufacture new medicines.

A glimpse into the past reveals a history of human enterprise that has adapted these tiny organisms for health and profit. This exhibition explores some of the processes, problems, and potential inherent in technologies that use life.

Close Menu ITEM 1 of 1

Half-Hours with the Microscope, Edwin Lankester, MD, illustrated by Tuffen West, 1860

Courtesy National Library of Medicine

-

EnlargeImage

-

Copy Link

Copied

Tinkering with DNA

All organisms, from microbes to humans, are governed by the genetic code embedded in their DNA. In the 1970s, scientists inserted a human gene into the genetic material of a common bacterium. This so—called "recombinant" microorganism could produce the protein encoded by the human gene.

Eager to explore the potential of this recombinant DNA technique, investors joined forces with research scientists to develop industrial applications. Two of the earliest products to reach the market were human insulin, used to treat diabetes, and human growth hormone, used in children with pituitary gland disorders.

Recombinant technology provided a commercially viable way to make proteins for medical use and gave rise to a new industry—dubbed "biotech."

Close Menu ITEM 1 of 5

Top: E.coli bacteria exchanging genes

Courtesy of Charles C. Brinton Jr.

Bottom: Views of E. coli bacteria by scanning electron microscope

Courtesy of David Scharf Photography

Escherichia coli (E. coli) bacteria are the workhorses of recombinant DNA technology. The ability of bacteria to easily exchange and absorb new pieces of DNA made them good vehicles for genetic engineering techniques.

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 2 of 5

Protropin, human growth hormone, 1987

Courtesy National Museum of American History

The Food and Drug Administration approved Protropin, human growth hormone made using genetically modified bacteria, for therapeutic use in 1985.

-

MedlinePlus

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 3 of 5

“First Man-made Protein in History,” LIFE, May 8, 1964

Courtesy © 1964 Time Inc. Reprinted with permission. All rights reserved. Image by Fritz Goro. ©Time Inc. Used with permission. All rights reserved.

In this illustration the sequences of colored balls represent the steps in a complex chemical process for building insulin molecules. Although this achievement was important for research, the process was not feasible for commercial insulin production.

-

MedlinePlus

-

Transcript

MEDICINE. The leader of the Pittsburgh team, Dr. P.G. Katsoyannis, here sits with LIFE’s schematic model of the components of synthetic insulin. The insulin molecule is represented by the wavy structure immediately above his head. Insulin is made up of two chains of amino acids, the building blocks of all living matter, represented by the colored balls. The steps to building the shorter or A chain are represented by the rectangular sequence at top. The build-up of the longer B chain is symbolized by the complex linkings below the insulin molecule. The Pittsburgh synthesis required over 200 delicate steps and five years to achieve. First Man-made Protein in History. The billiard player’s nightmare above is in fact a schematic model of a biochemist’s dream, with a happy ending. The model represents the intricate steps by which a protein has been synthesized for the first time. The protein is insulin and the difficult feat was achieved almost simultaneously by a team in Germany and one in the U.S. – at the University of Pittsburgh. Insulin is produced by the pancreas gland to aid in the conversion of sugar to body energy. A person whose pancreas does not produce enough of it suffers from diabetes. Up to now pancreases of animals have been the only source of insulin used for treatment of diabetics. The synthesis does not immediately create a new source of therapeutic insulin, although this indeed may happen. It does open significant areas of research and the possibility that a factory may one day be able to make more effective insulin than a pancreas.

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 4 of 5

“Ribbon Diagram” of human growth hormone, 2013

Courtesy National Center of Biotechnology Information (NCBI)

Ribbon diagrams are a graphic tool that helps researchers to visualize protein structures such as growth hormone. Understanding the relationship between DNA, genes, and protein structures led to the birth of genetic technologies including recombinant DNA.

In 1988, the National Center for Biotechnology Information was established at the National Library of Medicine to provide a central source for genetic and molecular data, including the gene sequences and structures of the proteins essential to human health.

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 5 of 5

How did they make insulin from recombinant DNA?

-

MedlinePlus

-

Copy Link

Copied

Harvesting Hormones

Hormones are complex molecules that regulate vital functions, including growth and development. In humans and animals, hormones are produced in glands and organs such as the pituitary, thyroid, and pancreas.

Before recombinant DNA technology, drug manufacturers extracted hormones, including insulin and growth hormone, directly from animal or human glands. Human growth hormone (hGH) required a supply of pituitary glands from human cadavers that was difficult to obtain.

The new technology ensured an abundant supply of these drugs. In the case of hGH, the number of children requiring it to treat pituitary gland disorders is quite small. However, with the supply secure new markets and applications emerged. The drug is used to increase height in otherwise healthy children, to enhance athletic performance, and to rejuvenate aging bodies.

Close Menu ITEM 1 of 21

“The position of the pituitary gland within the skull,” from The Pituitary Gland: Clinical Application of its Hormone Factors, Armour Laboratories, 1940s

Courtesy National Library of Medicine

The pituitary gland, the size of a chickpea, situated in the center of the brain, secretes nine different hormones, one of which regulates human growth.

-

MedlinePlus

-

Transcript

F. Netter M.D. The position of the pituitary gland within the skull showing relations to the sphenoidal sinus, etc. Insert shows detail of gland as it rests within the sella turcica–note membranes.

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 2 of 21

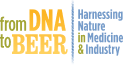

“How HGH Made One Dwarf Tall” LIFE, October 14, 1966

Courtesy © 1966 Time Inc. Reprinted with permission. All rights reserved. Images courtesy Royal Canadian Air Force.

A young man featured in Life magazine in 1966 gained 15 inches with the help of growth hormone injections. Although the extracted hormone was available for therapeutic use by the late 1950s, its availability was severely restricted by the limited supply of human glands.

-

MedlinePlus

-

Transcript

How HGH made one dwarf tall. One of the most striking cases of growth stimulated by injections of HGH is shown in these pictures of Frank Hooey. Above, prior to the treatment, Frank—then 15 and only 4’3” tall—stood next to a six–foot sergeant at Royal Canadian Air Force camp. Below, at 23, Franks stands in the kitchen doorway while his father records his new height—5’ 6 ½”.

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 3 of 21

“The Steer” from Armour’s Endocrine and Other Organotherapeutic Preparations, 1940s

Courtesy National Museum of American History

Diagram of glands and organs used for making pharmaceutical preparations.

-

MedlinePlus

-

EnlargeImage

-

Copy Link

Copied

-

Insulin sales kit, Eli Lilly and Company, 1940s

Courtesy National Museum of American History-

EnlargeImage

-

MedlinePlus

-

Copy Link

Copied

-

-

Insulin sales kit, Eli Lilly and Company, 1940s

Courtesy National Museum of American History-

EnlargeImage

-

MedlinePlus

-

Copy Link

Copied

-

-

Insulin sales kit, Eli Lilly and Company, 1940s

Courtesy National Museum of American History-

EnlargeImage

-

MedlinePlus

-

Copy Link

Copied

-

-

Insulin sales kit, Eli Lilly and Company, 1940s

Courtesy National Museum of American History-

EnlargeImage

-

MedlinePlus

-

Copy Link

Copied

-

-

Insulin sales kit, Eli Lilly and Company, 1940s

Courtesy National Museum of American History-

EnlargeImage

-

MedlinePlus

-

Copy Link

Copied

-

-

Insulin sales kit, Eli Lilly and Company, 1940s

Courtesy National Museum of American History-

EnlargeImage

-

MedlinePlus

-

Copy Link

Copied

-

-

Insulin sales kit, Eli Lilly and Company, 1940s

Courtesy National Museum of American History-

EnlargeImage

-

MedlinePlus

-

Copy Link

Copied

-

-

Insulin sales kit, Eli Lilly and Company, 1940s

Courtesy National Museum of American History-

EnlargeImage

-

MedlinePlus

-

Copy Link

Copied

-

-

Insulin sales kit, Eli Lilly and Company, 1940s

Courtesy National Museum of American History-

EnlargeImage

-

MedlinePlus

-

Copy Link

Copied

-

-

Insulin sales kit, Eli Lilly and Company, 1940s

Courtesy National Museum of American History-

EnlargeImage

-

MedlinePlus

-

Copy Link

Copied

-

-

Insulin sales kit, Eli Lilly and Company, 1940s

Courtesy National Museum of American History-

EnlargeImage

-

MedlinePlus

-

Copy Link

Copied

-

-

Insulin sales kit, Eli Lilly and Company, 1940s

Courtesy National Museum of American History-

EnlargeImage

-

MedlinePlus

-

Copy Link

Copied

-

-

Insulin sales kit, Eli Lilly and Company, 1940s

Courtesy National Museum of American History-

EnlargeImage

-

MedlinePlus

-

Copy Link

Copied

-

Insulin sales kit, Eli Lilly and Company, 1940s

Courtesy National Museum of American History

In the early 1920s, Canadian researchers isolated insulin from the pancreas glands of animals and successfully treated children with diabetes. They partnered with the American company Eli Lilly to mass produce this life–saving substance. This sales kit illustrates the step–by–step process for manufacturing insulin.

Close Menu ITEM 17 of 21

Insulin plasmid tubes, 1970s

Courtesy National Museum of American History

These tubes contained samples of bacterial DNA which had been genetically modified to contain the human insulin gene. Researchers used the DNA in the original experiments to produce human insulin from recombinant bacteria.

-

MedlinePlus

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 18 of 21

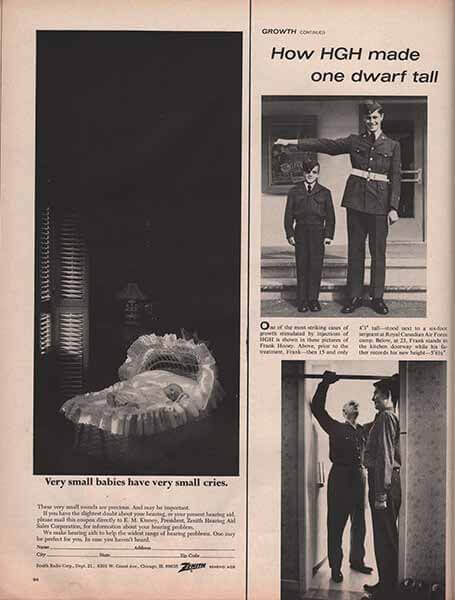

Pituitary gland products, 1910s–1950s

Courtesy National Museum of American History

These bottles contain medicines made from the pituitary glands of cattle. Although these tablets and powders were widely available, they were not effective. Any hormones present were destroyed by the human digestive system before they could work. In the 1940s, researchers isolated pure growth hormone from cattle glands. This hormone could be injected, but due to differences between species, bovine hormone was not effective for human use.

-

MedlinePlus

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 19 of 21

Grow Young with HGH by Dr. Ronald Klatz, 1998

Courtesy Harper Collins and National Museum of American History

-

MedlinePlus

-

Transcript

Grow Young With HGH. THE AMAZING MEDICALLY PROVEN PLAN TO: Lose Fat, Build Muscle, Reverse the Effects of Aging, Strengthen the Immune System, Improve Sexual Performance, Lower Blood Pressure and Cholesterol. BASED ON CUTTING-EDGE SCIENTIFIC RESEARCH. Dr. Ronald Klatz, President, American Academy of Anti-Aging Medicine. WITH CAROL KAHN

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 20 of 21

“My Little Brother on Drugs,” by Jenny Everett, Popular Science, April 2004

Used with permission of Popular Science Copyright ©2013. All rights reserved.

-

MedlinePlus

-

Transcript

MY LITTLE BROTHER ON DRUGS. Last July, 9–year–old Alex Everett received his first shot of synthetic human growth hormone—an injection he’ll get every night for eight years. Alex isn’t sick—he’s short. Should we be treating stature as a medical condition? By Jenny Everett. PHOTOGRAPHS BY JOHN B. CARNETT

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 21 of 21

Posilac, recombinant bovine growth hormone, Monsanto Company, 1994

Courtesy National Museum of American History

Following the success of human growth hormone (hGH), researchers developed a recombinant bovine (cow) growth hormone, which became available in 1994. The drug did not treat a disorder in cattle, but instead drug companies marketed the substance to dairy farmers to increase milk production.

-

DigitalCollections

-

MedlinePlus

-

EnlargeImage

-

Copy Link

Copied

Making Yellow Magic

Microbes are equipped with defense mechanisms to help ensure their survival. Penicillium, the bluish-green mold that grows on stale food, produces a substance that has the power to kill its bacterial competition. Many of these bacteria are also deadly to humans.

In the years leading into World War II, British scientists established the life-saving potential of Penicillium's natural antibiotic. Prompted by the war emergency, the United States government teamed with drug companies to mass-produce penicillin. The ability of the drug to prevent fatal infections among the wounded inspired the nickname "yellow magic."

The anti-infective power of penicillin and other antibiotics has led to their overuse in medicine and agriculture, resulting in the emergence of drug-resistant bacteria that threaten human health.

Close Menu ITEM 1 of 39

“The Era of Antibiotics,” painted by Robert A. Thom for Parke, Davis & Company, 1950s

Printed with Permission of American Pharmacists Association Foundation. Copyright 2009 APhA Foundation.

Penicillin research and production are depicted in this painting by Robert A. Thom, commissioned by Parke, Davis & Company as part of their “Great Moments in Pharmacy” advertising campaign in the 1950s.

-

MedlinePlus

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 2 of 39

“Thanks to Penicillin…He Will Come Home!” penicillin advertisement, Schenley Laboratories, 1944

Courtesy Schenley Laboratories, Inc.

Advertising played a role in establishing the image of penicillin as the wonder drug.

-

MedlinePlus

-

Transcript

Thanks to PENICILLIN…He Will Come Home! FROM ORDINARY MOLD—the Greatest Healing Agent of this War! On the gaudy, green–and–yellow mold above, called Penicillium notatum in the laboratory, grows the miraculous substance first discovered by Professor Alexander Fleming in 1928. Named penicillin by its discoverer, it is the most potent weapon ever developed against many of the deadliest infections known to man. Because research on molds was already a part of Schenley enterprise, Schenley Laboratories were well able to meet the problem of large–scale production of penicillin, when the great need for it arose. When the thunderous battles of this war have subsided to pages of silent print in a history book, the greatest news event of World War II may well be the discovery and development—not of some vicious secret weapon that destroys—but of a weapon that saves lives. That weapon, of course, is penicillin. Every day, penicillin is performing some unbelievable act of healing on some far battlefront. Thousands of men will return home who otherwise would not have had a chance. Better still, more and more of this precious drug is now available for civilian use…to save the lives of patients of every age. A year ago, production of penicillin was difficult, costly. Today, due to specially–devised methods of mass–production, in use by Schenley Laboratories, Inc. and the 20 other firms designated by the government to make penicillin, it is available in ever–increasing quantity, at progressively lower cost. Listen to “THE DOCTOR FIGHTS” starring RAYMOND MASSEY. Tuesday evenings, C.B.S. See your paper for time and station. SCHENLEY LABORATORIES, INC. Lawrenceburg, Indiana. Producers of PENICILLIN–Schenley

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 3 of 39

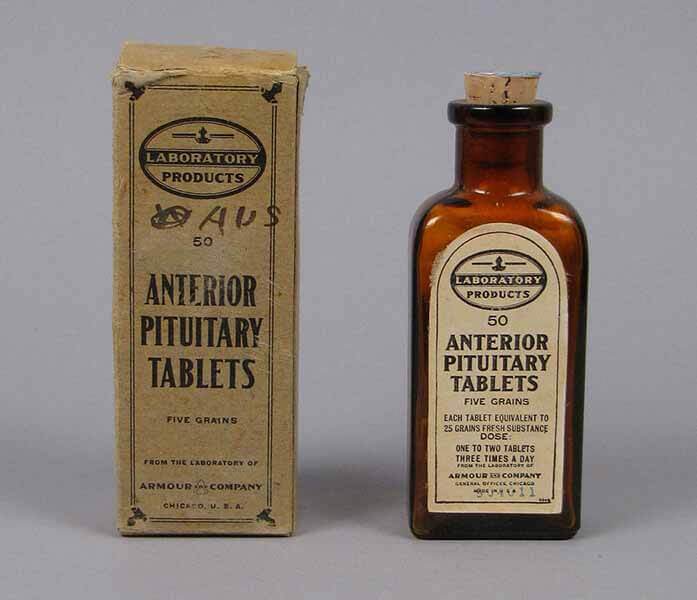

“Fibres and spores of Penicillium notatum” papenicillin advertisement, Squibb Laboratories, 1944

Courtesy National Museum of American History

“Growing in a liquid medium, this mold gives out golden droplets rich in penicillin—but the liquid must be concentrated over 30,000 times to obtain pure penicillin.”

-

MedlinePlus

-

Transcript

ABOUT PENICILLIN From Algiers comes this report by the Allied Medical Congress: “There never has been a therapeutic agent to compare with penicillin in its usefulness against a wide variety of diseases, including pneumonia, bone infections, syphilis, and a host of other infectious ‘ills’.” More than one hundred times as much penicillin is being made today as there was a year ago—and the cost has been reduced 84 percent. Remarkable changes have occurred in the method of manufacture since penicillin was first made at the Squibb Laboratories in 1940. Bottles once used for growing the mold have been replaced by huge tanks several stories high. Production time has been cut from two weeks to three days. Military needs come first, but production is now great enough to provide limited amounts of penicillin for civilian use. The House of Squibb is proud to have shared in the development of this new medicinal agent that now is man’s greatest defender against bacterial enemies. Through a microscope the fibres and spores of Penicillium notatum look like this. Growing in la liquid medium, this mold gives out golden droplets rich in penicillin—but the liquid must be concentrated over 30,000 times to obtain penicillin. The Squibb Laboratories were the first to obtain crystals of Penicillin Sodium from the natural product. New Squibb Penicillin Building. Giant tanks have replaced the glass bottles in which penicillin once grew so slowly. Instead of a few pounds, now over a ton of mold is grown each day, making possible a great increase in the production of penicillin. Unusual care maintains purity. Workers package penicillin in air–conditioned rooms, with ultraviolet lights to sterilize the air. For over two years, Squibb has been producing penicillin for the National Research Council and for the armed forces. Today, through designated hospitals, physicians can apply for the quantity of penicillin they need to treat infections. SQUIBB A name you can trust 7

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 4 of 39

Penicillin manufacture at Oxford University, early 1940s

Courtesy Sir William Dunn School of Pathology, Oxford University

Six “Penicillin Girls” nurtured the growing mold and harvested the penicillin from the hundreds of culture vessels at the manufacturing operation established at Oxford University in 1940.

-

MedlinePlus

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 5 of 39

Penicillin culture vessel, 1940

Courtesy National Museum of American History

-

MedlinePlus

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 6 of 39

Penicillin products from American manufacturers, 1940s

Courtesy National Museum of American History

Unable to establish large–scale commercial production, the British turned to the United States in 1942. More than twenty American drug companies joined the U.S. government’s penicillin production effort. Industrial fermentation tanks replaced small vessel production and by 1944 penicillin supplies met military needs.

-

MedlinePlus

-

EnlargeImage

-

Copy Link

Copied

-

Yellow Magic: The Story of Penicillin, by J. D. Ratcliff, 1945

Courtesy Random House-

EnlargeImage

-

Transcript

Title page that reads “Yellow Magic: The Story of Penicillin by J. D. Ratcliff. Random House—New York”

-

Copy Link

Copied

-

-

Yellow Magic: The Story of Penicillin, by J. D. Ratcliff, 1945

Courtesy Random House-

EnlargeImage

-

Transcript

Photo of the outside of a penicillin plant featuring many cylindrical towers, tanks, and connecting pipes with caption text reading — “Penicillin, which started life as a laboratory curiosity, has grown into a giant industry. Over $20,000,000 has been spent on plants such as this.”

-

Copy Link

Copied

-

-

Yellow Magic: The Story of Penicillin, by J. D. Ratcliff, 1945

Courtesy Random House-

EnlargeImage

-

Transcript

Photo of eight conical Erlenmyer flasks containing Penicillium mold with caption text reading—“Microphotograph of fronds of Penicillium mold. The crinkled green mold growing in these flasks is Penicillium notatum, producer of penicillin. The magic drug is found in the broth on which the mold grows.”

-

Copy Link

Copied

-

-

Yellow Magic: The Story of Penicillin, by J. D. Ratcliff, 1945

Courtesy Random House-

EnlargeImage

-

Transcript

Photo of two hands holding a petri dish showing circular areas where penicillin killed bacterial growth with caption text reading—“Rings on the plate show where penicillin has destroyed microbes.”

-

Copy Link

Copied

-

-

Yellow Magic: The Story of Penicillin, by J. D. Ratcliff, 1945

Courtesy Random House-

EnlargeImage

-

Transcript

Photo of two people in gowns, hoods and face masks pour liquid from one large conical flask into another with caption text reading—“When mold growth is complete, the broth containing penicillin is harvested under rigidly aseptic conditions. Such necessary precautions account for penicillin’s high cost.”

-

Copy Link

Copied

-

-

Yellow Magic: The Story of Penicillin, by J. D. Ratcliff, 1945

Courtesy Random House-

EnlargeImage

-

Transcript

Photo of man in white gown holds a mouse while a woman injects penicillin into the mouse’s tail end with caption text reading—“Each batch of drug produced must be tested for impurities. These mice will tell whether the drug contains any toxic contaminants.”

-

Copy Link

Copied

-

-

Yellow Magic: The Story of Penicillin, by J. D. Ratcliff, 1945

Courtesy Random House-

EnlargeImage

-

Transcript

Photo of nine rabbits held in a long stockade style box. A woman in white lab coat holding a thermometer stands next to them with caption text reading—“Rabbits in this test tell whether penicillin contains any fever-producing impurities. If rabbit temperatures rise perceptibly the penicillin under test is discarded.”

-

Copy Link

Copied

-

-

Yellow Magic: The Story of Penicillin, by J. D. Ratcliff, 1945

Courtesy Random House-

EnlargeImage

-

Transcript

Photo of trays with small bottles on a large circular surface; workers are visible around the perimeter with caption text reading—“Finished penicillin must be bottled under conditions far more sterile than those prevailing in any operating room. Microbe–killing ultra–violet lamps shine on the workers in these pictures. The rooms are under slight pressure so that sterile air will leak out, instead of contaminated outside air leaking in.”

-

Copy Link

Copied

-

-

Yellow Magic: The Story of Penicillin, by J. D. Ratcliff, 1945

Courtesy Random House-

EnlargeImage

-

Transcript

Photo of an enlarged view of penicillin crystals with caption text reading—“This picture shows pure, crystalline penicillin, produced at enormous cost. Study of such crystals will give chemists clues about making the drug synthetically.”

-

Copy Link

Copied

-

Yellow Magic: The Story of Penicillin, by J. D. Ratcliff, 1945

Courtesy Random House

-

“Penicillin Issue” cover of Journal of the American Pharmaceutical Association, April 1945

Courtesy National Museum of American HistoryIn April 1945, the American Pharmaceutical Association published a special penicillin issue to educate retail pharmacists about the new drug. Companies engaged in penicillin manufacture used the opportunity to promote their brand and stake a claim in the expanding market.-

EnlargeImage

-

Transcript

VOL. VI, NO. 4 1945 Journal of the AMERICAN PHARMACEUTICAL ASSOCIATION [Cover image shows a medicine bottle with labeled “Penicillin Sodium” with line drawing of three buildings with the sign “DRUGS” on each.] Practical Pharmacy Edition PENICILLIN ISSUE [A label on the left side reads, “To be kept in LABORATORY, Rouse’s Drug Store, Beaver, PA, PHONE 1066”]

-

Copy Link

Copied

-

-

“Penicillin Issue” cover of Journal of the American Pharmaceutical Association, April 1945

Courtesy National Museum of American HistoryIn April 1945, the American Pharmaceutical Association published a special penicillin issue to educate retail pharmacists about the new drug. Companies engaged in penicillin manufacture used the opportunity to promote their brand and stake a claim in the expanding market.-

EnlargeImage

-

Transcript

Pharmaceutical advertisement with photographs of factories, physicians, vials and packaging. NOW Released for Distribution Through Prescription Pharmacies Penicillin, Abbott Views of Abbott’s great new Penicillin plant in North Chicago Backed by the force of the Abbott nation-wide program of detailing Advertising of Penicillin, Abbott, to physicians now greatly increased Selling helps designed to increase profits and enhance your prestige A LEADER IN PENICILLIN RESEACH AND PRODUCTION Stock, Feature and Push PENICILLIN, ABBOTT, NOW Because— 1. You will gain both profit and professional prestige by being among the first to distribute this dramatic life–saving drug in your community. 2. Penicillin, Abbott, is backed by more than three years of research, d development and manufacturing experience in this important field by one of America’s foremost makers of ethical research products for medicinal use- a manufacture whose name is your guarantee of immediate and maximum physician acceptance. 3. Specification and preference for Penicillin, Abbott, are now being created by one of the most effective detailing organization in the county. 4. Penicillin, Abbott, has been advertised in the United States for more than a year and a half. 5. Advertising of Penicillin, Abbott, to physicians is now stepped up to truly major scale. 6. You are given, free of charge, immediate, direct and effective aid in channeling professional demand for Penicillin to your pharmacy. First, with your initial order for Penicillin, Abbott, your will be supplied, upon request, thirty bulletin cards, printed on Government postals and imprinted with your store name and address, all ready for mailing to physicians in your neighborhood of community, to tell them that you have the Abbott brand of this important drug in stock for their needs. Second, with your initial order, you are supplied with the beautiful, prestige–building counter or hanging sign illustrated at the lower left—a sign which emphasizes your importance as a professional man who is abreast of the most recent medical advances. Order at once through your usual source of supply. Mention the sign and bulletin cards if you’d like them, giving imprint copy for the latter. Penicillin, Abbott, is supplied in cartons of five 20–cc. rubber-capped vials, each containing 100,000 Oxford units of Penicillin and one 20–cc. vial of sterile isotonic sodium chloride solution, U.S.P., to be used as a solvent. We suggest that about one–third of your total order be for the Combination Packages—And that you act immediately. A product with a brand name which assures wide physician acceptance. Abbott Laboratories — North Chicago, Illinois

-

Copy Link

Copied

-

-

“Penicillin Issue” cover of Journal of the American Pharmaceutical Association, April 1945

Courtesy National Museum of American HistoryIn April 1945, the American Pharmaceutical Association published a special penicillin issue to educate retail pharmacists about the new drug. Companies engaged in penicillin manufacture used the opportunity to promote their brand and stake a claim in the expanding market.-

EnlargeImage

-

Transcript

JOURNAL OF THE AMERICAN PHARMACEUTICAL ASSOCIATION WHY IT WILL PAY YOU TO SELL Penicillin-C.S.C.-made in one of the world’s largest plants, equipped for foremost efficacy and integrity of production — is backed by 25 years of research and experience in large–scale manufacture by microbiotic procedures. It is assayed, bacteriologically as well as biologically, to safeguard its potency, sterility, nontoxicity, and freedom from fever–inducing pyrogens. The high state of purification reached by Penicillin–C.S.C. is indicated by the notably small amount of substance required in the vial to present 100,000 Oxford Units. It assures high therapeutic efficacy and virtual freedom from the undesirable reactions attributed by many investigators to inadequate purification. The enormous production of Penicillin–C.S.C.–fully 800,000 vials of 100,000 Oxford Units each per month — assures you of adequate supply. Your orders will not be “shorted.” 1. Vial Filling; note precautions used. 2. Drying Penicillin–C.S.C. under high vacuum. 3. Vial sealing and capping. 4. Testing for nontoxicity. Mention the Journal of the A. Ph. A. when writing advertisers—It identifies you. ADVERTISERS’ SECTION PENICILLIN–C.S.C Preferentially No other penicillin has been so widely promoted to the medical profession, in a long list of medical journals, by mail, and through helpful scientific literature. Every physician knows Penicillin–C.S.C. and ranks it high. There will be no “sales resistance” when you offer it preferentially. No need of a large stock for you; your wholesaler is supplied, and will always be able to replenish your stock quickly. Make your pharmacy a “library of information” on penicillin by writing us for your copies of the three pieces here shown — the Penicillin–C.S.C. Reporter, presenting abstracts of latest publications, the Penicillin–C.S.C. Therapeutic Reference Table, and a comprehensive brochure. PHARMACEUTICAL DIVISION COMMERCIAL SOLVENTS Corporation 17 East 42nd Street New York 17, N.Y. The combination package provides two vials — one containing 100,000 Oxford Units of Penicillin–C.S.C., the other 20 cc. of pyrogen–free normal saline solution. Mention the Journal of the A. Ph. A. when writing advertisers—It identifies you.

-

Copy Link

Copied

-

-

“Penicillin Issue” cover of Journal of the American Pharmaceutical Association, April 1945

Courtesy National Museum of American HistoryIn April 1945, the American Pharmaceutical Association published a special penicillin issue to educate retail pharmacists about the new drug. Companies engaged in penicillin manufacture used the opportunity to promote their brand and stake a claim in the expanding market.-

EnlargeImage

-

Transcript

PENICILLIN—Heyden The package illustrated is supplied to the Armed Forces and for direct export, Distributors of Heyden Penicillin in the United States sell under their own labels. A pioneer producer of Penicillin, Heyden is proud to announce the position it has achieved through the efforts of the combined Heyden scientific and technical staffs. Industrial fermentation processes have been a subject of close study by the Heyden research organization over a long period of years. Benefits accruing from this work have contributed materially in the production of Penicillin. Commercial production began early in 1944, following active participation in the Research Program sponsored by the Office of Scientific Research and Development and the War Production Board. Heyden is now a leading producer of Penicillin, Penicillin Sodium–Heyden has been accepted by the Council on Pharmacy and Chemistry of the American Medical Association. Over and above the needs of the Armed Forces, a substantial percentage of the Penicillin production is now made available for civilian use through distributors of the Heyden product. Penicillin for research use is supplied direct from Heyden to the user. As a service to research laboratories and the industries, an efficient consulting staff is available for discussion of new applications of Penicillin and its derivatives. HEYDEN Chemical Corporation 393 Seventh Avenue, New York 1, N.Y. Benzaldehye, Benzoates, Benzoic Acid, Benzyl Chloride, xx, xx, Medicinal Creosotes, Formates, Formaldehyde, Formic Acid, Glycerophosphates, Medicinal Guaiocols, xx, xx, Parahydroxybenzoates, Penicillin, Pentaerythritols, Salicylates

-

Copy Link

Copied

-

-

“Penicillin Issue” cover of Journal of the American Pharmaceutical Association, April 1945

Courtesy National Museum of American HistoryIn April 1945, the American Pharmaceutical Association published a special penicillin issue to educate retail pharmacists about the new drug. Companies engaged in penicillin manufacture used the opportunity to promote their brand and stake a claim in the expanding market.-

EnlargeImage

-

Transcript

ADVERTISERS’ SECTION XIII PENICILLIN…PENICILLIN…PENICILLIN…PENICILLIN… RELIABILITY, UNIFORMITY, PURITY, EFFICACY, E.R. SQUIBB & SONS Now that you can stock penicillin… What brand will your doctors want? There are many sound reasons why physicians will specify Penicillin Squibb. A pioneer in penicillin research, Squibb was one of the three original American companies to receive the first Oxford culture from England in 1940. From that day, Squibb has been identified with every landmark in penicillin development from petri dish to mass production in fifteen–thousand–gallon fermentation tanks. That is why Squibb not only stands in the first rank of the world’s largest penicillin producers, but also makes a penicillin unexcelled for potency, purity and dependability. For 87 years, the name Squibb has meant fine pharmaceuticals—products physicians can trust. Every single vial of Penicillin Squibb is made by Squibb, under rigid Squibb control, by methods perfected in the Squibb Development and Manufacturing Laboratories. You will have many calls for Penicillin Squibb. Place your orders now! SQUIBB Penicillin SODIUM MANUFACTUING CHEMISTS TO THE MEDICAL PROFESSION SINCE 1858 Mention the Journal of the A. Ph. A. when writing advertisers—It identifies you

-

Copy Link

Copied

-

-

“Penicillin Issue” cover of Journal of the American Pharmaceutical Association, April 1945

Courtesy National Museum of American HistoryIn April 1945, the American Pharmaceutical Association published a special penicillin issue to educate retail pharmacists about the new drug. Companies engaged in penicillin manufacture used the opportunity to promote their brand and stake a claim in the expanding market.-

EnlargeImage

-

Transcript

ADVERTISERS’ SECTION XIII PENICILLIN…PENICILLIN…PENICILLIN…PENICILLIN… RELIABILITY, UNIFORMITY, PURITY, EFFICACY, E.R. SQUIBB & SONS Now that you can stock penicillin… What brand will your doctors want? There are many sound reasons why physicians will specify Penicillin Squibb. A pioneer in penicillin research, Squibb was one of the three original American companies to receive the first Oxford culture from England in 1940. From that day, Squibb has been identified with every landmark in penicillin development from petri dish to mass production in fifteen–thousand–gallon fermentation tanks. That is why Squibb not only stands in the first rank of the world’s largest penicillin producers, but also makes a penicillin unexcelled for potency, purity and dependability. For 87 years, the name Squibb has meant fine pharmaceuticals—products physicians can trust. Every single vial of Penicillin Squibb is made by Squibb, under rigid Squibb control, by methods perfected in the Squibb Development and Manufacturing Laboratories. You will have many calls for Penicillin Squibb. Place your orders now! SQUIBB Penicillin SODIUM MANUFACTUING CHEMISTS TO THE MEDICAL PROFESSION SINCE 1858 Mention the Journal of the A. Ph. A. when writing advertisers—It identifies you.

-

Copy Link

Copied

-

-

“Penicillin Issue” cover of Journal of the American Pharmaceutical Association, April 1945

Courtesy National Museum of American HistoryIn April 1945, the American Pharmaceutical Association published a special penicillin issue to educate retail pharmacists about the new drug. Companies engaged in penicillin manufacture used the opportunity to promote their brand and stake a claim in the expanding market.-

EnlargeImage

-

Copy Link

Copied

-

-

“Penicillin Issue” cover of Journal of the American Pharmaceutical Association, April 1945

Courtesy National Museum of American HistoryIn April 1945, the American Pharmaceutical Association published a special penicillin issue to educate retail pharmacists about the new drug. Companies engaged in penicillin manufacture used the opportunity to promote their brand and stake a claim in the expanding market.-

EnlargeImage

-

Transcript

ADVERTISERS’ SECTION XV Wyeth REG. U.S. PAT. OFF. THE WYETH VIPULE GIVES YOU “Laboratory fresh” PENICILLIN SOLUTION The Vipule is a special glass container in which Penicillin, Wyeth, is reduced to a dry powder from the frozen state under high vacuum. The flame-sealed Vipule container, exclusively Wyeth, provides prolonged protection of the delicate product against air, moisture, and other deleterious influences. Unbroken, the Vipule retains the potency of the penicillin so effectively that it remains stable over long periods…a highly important feature with this sensitive antibiotic. THE VIPULE provides a Closed-System technique for restoring penicillin into “LABORATORY FRESH” sterile solution. THE WYETH VIPULE* PENICILLIN PACKAGE: The Closed- System Unit One Vipule contains 100,000 Oxford units of Penicillin, Wyeth; the other Vipule containing the diluent (20 cc. of sterile, pyrogen-free normal saline solution) is fitted with double-pointed Vipule needle. Solutions are prepared quickly without the aid of a syringe: 1. Snap the glass cap from the penicillin Vipule at the plainly visible etched groove. Turn down sleeve of rubber stopper over neck of Vipule. 2. Snap the cap from the Vipule with diluent to expose the free end of the double-pointed Vipule needle. 3. Invert vial portion of the diluent Vipule over the upright penicillin vial and push downward so that the ends of the needle penetrate both diaphragms. The “Laboratory Fresh” Penicillin solution is now ready for withdrawal and administration. *REG. U.S. PAT. OFF. REICHEL DIVISION WYETH INCORPORATED PHILADELPHIA 3, PA. Wyeth Mention the Journal of the A. Ph. A. when writing advertisers—It identifies you.

-

Copy Link

Copied

-

“Penicillin Issue” cover of Journal of the American Pharmaceutical Association, April 1945

Courtesy National Museum of American History

Close Menu ITEM 17 of 39

Soil sample, Charles Pfizer and Company, 1949

Courtesy National Museum of American History

Soil, naturally rich in microbial life, became an important source for antibiotic discovery. The Pfizer company alone tested over 100,000 soil samples from around the world, as drug companies competed to develop new products. This envelope of soil, from a cornfield in the Midwest, yielded a winning microbe and led to a successful new antibiotic named Terramycin.

-

MedlinePlus

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 26 of 39

“A handful of earth that may save your life“ penicillin advertisement, Parke, Davis & Company, 1962 Copyright © Pfizer Inc. All rights reserved.

The Parke Davis company tested thousands of soil samples each year for new microorganisms. Advertisements in popular magazines highlighted the enormous research effort required to produce one or two useful products.

-

MedlinePlus

-

Transcript

A handful of earth that may save your life This scene might have happened anywhere in the world — a wilderness in Borneo, a plantation in Brazil, a sheep ranch in New Zealand, a back yard in the U.S.A. From this field comes one of thousands of soil samples sent year after year to our Parke–Davis research laboratories. By using new microorganisms from these samples, we are trying to create antibiotics to combat the uncontrolled infectious diseases still rampant. For example, in one year, Parke–Davis scientists isolated and worked with 34,000 cultures of microorganisms. With these, they produced a few antibiotics which came excitingly close to meeting our exacting standards of acceptability, but none made the grade. Perhaps 34,000 to 0 seem like poor odds, but twice in recent years research work at Parke–Davis has beat these odds to provide antibiotics now used around the world. Parke–Davis frequently takes calculated risks. A miss doesn’t discourage us. Your health and your family’s health demand out continued efforts. Copyright 1962–Parke, Davis & Company, Detroit 32. Mich. PARKE–DAVIS …PIONEERS IN BETTER MEDICINES

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 27 of 39

Polycillin oral antibiotic, Bristol–Myers Company, 1977

Courtesy National Museum of American History

New penicillins, such as ampicillin (brand name Polycillin) developed in the 1960s, were effective for treating many common infections. Oral formulas made taking the medicine more convenient. Doctors and patients came to rely on antibiotics even in uncertain diagnoses.

-

MedlinePlus

-

EnlargeImage

-

Copy Link

Copied

-

Terramycin products, Charles Pfizer and Company, early 1960s

Courtesy National Museum of American HistoryAntibiotics provided livestock producers with a means to control the infections that spread quickly through large herds and feed lots. Researchers discovered that these antibiotics also had the beneficial side effect of promoting growth. As a result, drug companies developed low– dose antibiotic products that could be added to the daily feed.-

EnlargeImage

-

Copy Link

Copied

-

-

Terramycin products, Charles Pfizer and Company, early 1960s

Courtesy National Museum of American HistoryAntibiotics provided livestock producers with a means to control the infections that spread quickly through large herds and feed lots. Researchers discovered that these antibiotics also had the beneficial side effect of promoting growth. As a result, drug companies developed low– dose antibiotic products that could be added to the daily feed.-

EnlargeImage

-

Copy Link

Copied

-

-

Terramycin products, Charles Pfizer and Company, early 1960s

Courtesy National Museum of American HistoryAntibiotics provided livestock producers with a means to control the infections that spread quickly through large herds and feed lots. Researchers discovered that these antibiotics also had the beneficial side effect of promoting growth. As a result, drug companies developed low– dose antibiotic products that could be added to the daily feed.-

EnlargeImage

-

Copy Link

Copied

-

-

Terramycin products, Charles Pfizer and Company, early 1960s

Courtesy National Museum of American HistoryAntibiotics provided livestock producers with a means to control the infections that spread quickly through large herds and feed lots. Researchers discovered that these antibiotics also had the beneficial side effect of promoting growth. As a result, drug companies developed low– dose antibiotic products that could be added to the daily feed.-

EnlargeImage

-

Copy Link

Copied

-

-

Terramycin products, Charles Pfizer and Company, early 1960s

Courtesy National Museum of American HistoryAntibiotics provided livestock producers with a means to control the infections that spread quickly through large herds and feed lots. Researchers discovered that these antibiotics also had the beneficial side effect of promoting growth. As a result, drug companies developed low– dose antibiotic products that could be added to the daily feed.-

EnlargeImage

-

Copy Link

Copied

-

-

Terramycin products, Charles Pfizer and Company, early 1960s

Courtesy National Museum of American HistoryAntibiotics provided livestock producers with a means to control the infections that spread quickly through large herds and feed lots. Researchers discovered that these antibiotics also had the beneficial side effect of promoting growth. As a result, drug companies developed low– dose antibiotic products that could be added to the daily feed.-

EnlargeImage

-

Copy Link

Copied

-

Terramycin products, Charles Pfizer and Company, early 1960s

Courtesy National Museum of American History

Close Menu ITEM 29 of 39

“Pig’s Progress” LIFE, December 3, 1951

Courtesy © 1951 Time Inc. Reprinted with permission. All rights reserved. Image by Albert Fenn. ©Time Inc. Used with permission. All rights reserved.

A piglet thrives on a formula of artificial milk and Terramycin, an antibiotic, developed to accelerate growth in animals.

-

MedlinePlus

-

Transcript

IN A CAGE IN PFIZER & CO.’S HATCHERY A SATIATED SUCKLING PIG, ITS EYES HALF CLOSED WITH SLEEP, STILL GREEDILY GUZZLES ITS SYNTHETIC SUPPER PIG’S PROGRESS Taken from sow soon after birth it thrives happily on a new diet The seven–day–old suckling, happily drinking artificial milk from an artificial sow, is taking part in the early stages of a major revolution in animal husbandry. Normally pig litters must be kept with sows until weaning time. During this period nearly a third of all pigs born die, either from undernourishment, disease or accidents. The artificial milk, newly produced by Chas. Pfizer & Co., contains all the nutrients a little pig needs and makes practicable for the first time the feeding of piglets from racks of bottles rather than their mothers’ teats. The milk also contains the antibiotic Terramycin, which accelerates pigs’ growth (p. 161). Taken from the mothers 48 hours after birth piglets can be raised safely and quickly on a hatchery scale, like chicks. This in turn could make possible a 25% increase in U.S. pork production.

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 30 of 39

“How Meat Serves Everybody!“ Life, November 14, 1949

Courtesy National Museum of American History

Meat production and consumption expanded rapidly along with the prospering American economy in the years following World War II. This advertisement from the American Meat Institute emphasizes the benefits of meat for human health, the economy, and soil conservation.

-

MedlinePlus

-

Transcript

MEAT SERVES EVERYBODY This country isn’t just 48 states. This country is 40,000,000 families. As the vigor of mothers, fathers, boys and girls goes— so goes the vigor of our nation. the people… Meat is more than something to eat. It helps you hit the ball harder, run the race faster, do the thing better. It is paint that helps make cheeks rosy. It is fuel for endurance— for nerve— for fun— for strength. It helps the child to grow. It helps the man to work. It helps the woman to be at her best— the wife to have healthy children. It helps the older person to do and keep doing. Besides contributing to a diet that helps keep bodies strong, the meat industry is the source of dozens of vital medicinal products such as insulin, thyroid and pituitary extract that are essential to saving life, prolonging life and keeping people health. These products are used in diabetes, heart cases, shock, anemia, pregnancy and general surgery. the soil… You have seen the gullied, over—cropped and worn—out fields that dot our countrysides— and you’re seeing them brought back to fertility— and producing food at the same time— through new emphasis on livestock raising. Grass roots tie down the soil. Forage crops like clover and alfalfa help restore its fertility. the nation! The experts who calculate America’s real wealth know that the only things that count are those that can be put to use by people. We can’t eat grass, but meat animals convert the grass from vast range lands of the West into human food. They turn hay crops and feed grains— even waste products like sugar beet pulp— into nourishing meat. If Mother Nature produces more of almost any food crop than people want, livestock can convert that into meat, too. THE MEAT TEAM from Farm to Plant to Store America’s meat needs are served through the teamwork of ranchers and farmers, packers and retailers, backed up by the people who run the trains and trucks, who operate the nation’s stockyards— the commission men who sell the farmers’ livestock, the meat wholesalers and many others. Through their teamwork meat moves from farm to table at a lower service cost than almost any other food. AMERICAN MEAT INSTITUTE Headquarters, Chicago—Members throughout the U.S.

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 39 of 39

How did they make penicillin?

-

MedlinePlus

-

EnlargeImage

-

Copy Link

Copied

Living Factories

Humans and animals have natural defense systems that produce antibodies in the blood to combat bacteria and other harmful substances invading the body. In the late nineteenth century, scientists investigating this immune response in animals developed new methods for treating diseases in humans.

One of these early therapies used blood serum, collected from animals inoculated with toxins from bacteria. The natural protection these animals developed against the toxin could be passed to humans through injections of the serum. In commercial production, horses and other large animals served as living serum factories to grow the so—called "antitoxins" for human use.

Serum therapy provided an effective cure for diphtheria, an often fatal childhood disease. The demand for serum established a new drug industry that required the use of large numbers of animals for production.

Close Menu ITEM 1 of 27

Recovering the diphtheria serum from horse blood in Marburg, Germany, drawn from nature by Fritz Gehrke, 1890s

Courtesy of National Library of Medicine

-

MedlinePlus

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 2 of 27

Guinea pigs used for testing serums and toxins at Parke Davis & Company, ca. 1925

Courtesy National Museum of American History

-

MedlinePlus

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 3 of 27

Guinea pig room at Parke Davis & Company, ca. 1925

Courtesy National Museum of American History

-

MedlinePlus

-

EnlargeImage

-

Copy Link

Copied

-

Intubation kit, ca. 1898

Courtesy National Museum of American HistoryThis intubation kit includes a set of seven tubes, sized for children up to age twelve, along with the tools used for inserting and extracting the tubes from the throat.-

EnlargeImage

-

Copy Link

Copied

-

-

(Top) Metal extractor tool from intubation kit, c. 1898/(Bottom) O’Dwyer’s improved extractor from Intubation of the Larynx, F.E. Waxham, 1888

Courtesy National Museum of American History/Courtesy National Library of MedicineThe extraction tool has a pincer end that grabs the intubation tube from the throat before pulling it out of the patient. The illustration shows how the lever by the handle operates the pincer for latching onto the tube.-

EnlargeImage

-

Copy Link

Copied

-

-

(Left) Hard rubber intubation tubes arranged by length, c. 1898/(Right) Cross section of mouth and neck anatomy from Intubation of the Larynx, F.E. Waxham, 1888

Courtesy National Museum of American History/Courtesy National Library of MedicineThis kit includes seven hard rubber intubation tubes that vary in their lengths and widths in order to accommodate the windpipe of children up to age 12. The tube has an elliptical, enlarged head and bulging middle, designed to keep it in place in the throat. The illustration shows the placement of the inserted tube in the windpipe.-

EnlargeImage

-

Copy Link

Copied

-

-

(Left) Metal insertion tool from intubation kit, c. 1898/(Right) Metal insertion tool from Intubation of the Larynx, F.E. Waxham, 1888

Courtesy National Museum of American History/Courtesy National Library of MedicineThe metal insertion tool has a tube holding attachment (bent end) where the black intubation tube is fitted. The long neck of the tool is long enough to reach into the patient’s mouth and insert the tube in the patient’s windpipe.-

EnlargeImage

-

Copy Link

Copied

-

-

(Left) Metal mouth gag from intubation kit, c. 1898/(Right) “Proper position of operator and attendants” from Intubation of the Larynx, F.E. Waxham, 1888

Courtesy National Museum of American History/Courtesy National Library of MedicineThe mouth gag tool keeps the patient’s mouth open for inserting or extracting the intubation tube. The illustration shows how a young patient is held securely by a person, behind whom another individual stands and holds the patient’s mouth open using the gag tool.-

EnlargeImage

-

Copy Link

Copied

-

Intubation

-

Anti–Diphtheritic Serum and syringes, Parke, Davis & Company, ca. 1898

Courtesy National Museum of American History-

EnlargeImage

-

Copy Link

Copied

-

-

Anti-–Diphtheritic Serum, Parke, Davis & Company, ca. 1898

Courtesy National Museum of American History-

EnlargeImage

-

Copy Link

Copied

-

-

Anti–Diphtheritic Serum, Parke, Davis & Company, ca. 1898

Courtesy National Museum of American History-

EnlargeImage

-

Copy Link

Copied

-

-

Instruction sheet for Anti–Diphtheritic Serum, Parke, Davis & Company, ca. 1898

Courtesy National Museum of American History-

EnlargeImage

-

Copy Link

Copied

-

-

Anti–Diphtheritic syringes, Parke, Davis & Company, ca. 1898

Courtesy National Museum of American History-

EnlargeImage

-

Copy Link

Copied

-

-

Anti–Diphtheritic syringes, Parke, Davis & Company, ca. 1898

Courtesy National Museum of American History-

EnlargeImage

-

Copy Link

Copied

-

Anti-Diphtheritic Serum

Close Menu ITEM 10 of 27

Injecting diphtheria antitoxin, 1895

Courtesy The Historical Medical Library of The College of Physicians of Philadelphia

-

MedlinePlus

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 15 of 27

“How New York City’s Health Department Makes Serums and Vaccines for the United States Army?” Popular Science, December 1917

Courtesy Smithsonian Libraries, The National Museum of American History Library

-

MedlinePlus

-

Transcript

How New York City’s Health Department Makes Serums and Vaccines for the United States Army Preparing the Bacteria In the preparation of typhoid vaccine the bacteria are grown in the bottles you see on the table. The germs are killed by pouring a salt solution over them. The bottle on the shelf contains the salt solution which is being siphoned into the bottle containing the colony of typhoid fever germs. Transferring the Bacilli Tetanus bacilli occur in dust, earth and manure. They do not grow in the presence of oxygen and are particularly dangerous if they get into deep wounds. The young lady in the photograph is drawing up tetanus bacilli from the bottom of a test tube be means of a glass tube which she holds in her mouth. Thus the germs are transferred from tube to tube. The Resultant Powerful Toxin Here the large flask is being inoculated with tetanus bacilli. The small wire basket at the right contains test tubes in which are the tetanus germs. The flame which you see just to the right of the flask which is being inoculated is kept burning so that any instrument may be immediately sterilized after exposure. The Final Step The finished product containing millions of dead typhoid fever bacilli is poured by means of a siphon into large bottles. The vaccine is kept in a refrigerator until it is needed for use. Note the milky appearance of the vaccine. A Glimpse into the “Shop” of the Laboratories This photograph shows the refrigerator in the Bacteriological Laboratories of the Department of Health of the City of New York, where serums, vaccines and anti–toxins are prepared for the use of the United States Army. Much of this material will be shipped to the front. In the containers and bottles which you see on the shelves is $150,000 worth of material. There is enough diphtheria antitoxin to treat 75,000 men, enough tetanus antitoxin for 200,000 men, enough smallpox vaccine for a half million men and enough antimeningococcus serum to treat 2,500 men suffering from cerebrospinal meningitis. Bleeding the Horse to Obtain the Serum After the horse has been inoculated with the disease poison in gradually increasing doses he is bled and his serum is found to be antitoxin. This is administered to human beings and renders them immune to the disease. The horses are kept in the pink of condition. At periodic intervals they are given a rest. During the rest periods they are turned out to grass. When thoroughly rested, they are inoculated again. Some horses give more antitoxin serum than others. The same horse may be used at several different times for the preparation of distinctly different antitoxins. Inoculating a Horse with Toxin One of the 73 horses in the stables of the Department of Health of the City of New York at Ctisville. This horse is being inoculated with diphtheria toxin. Small doses gradually increased render the horse immune to diphtheria. Horses are used in the preparation of diphtheria, tetanus antitoxin and antimeningococcus serum.

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 16 of 27

“The Voges holder for guinea–pigs” from The Principles of Bacteriology by Alexander Crever Abbott, 1899

Courtesy National Museum of American History

This tube was used to immobilize guinea pigs during inoculations. Injections of toxins and serums were administered through the cut–out window. Although their role was less publicized, small mammals, such as the guinea pig, were essential to the serum manufacturing process.

-

MedlinePlus

-

Transcript

SUBCUTANEOUS INOCULATION OF ANIMALS 237 In such a cylinder with its head toward the perforated bottom. It is then easily possible to make subcutaneous inoculation by taking up a bit of skin through the slit in the FIG. 42 The Voges–holder for guinea pigs. Side of the box, or to make the intraperitoneal injection by drawing the posterior extremities slightly from the box and holding them steady between the index and second finger, as seen in FIG. 42. It is also very convenient for use when the

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 17 of 27

Guinea pig holder, early 20th century

Courtesy National Museum of American History

-

MedlinePlus

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 18 of 27

Animal Record Card from Hygienic Laboratory Bulletin No. 21, 1905

Courtesy National Library of Medicine

Animal Record Card for a guinea pig used in serum and toxin testing. Pig No. 1567 is identified by a rough sketch of its color markings.

-

MedlinePlus

-

Transcript

TREASURY DEPARTMENT PUBLIC HEALTH AND MARINE—HOSPITAL SERVICE, HYGENIC LABORATORY—Form No. 0007 ANIMAL RECORD CARD Subject: Diphtheria Lt Weight: 250 No. 1567 Operator: MyR Marks: (female symbol) Own raising Date: 1–25, 1905, 3pm t Date: 1–29, 1905, 5pm .22 02 Tox. *7 + 1 I.E. Ehrlich 15–11–05 Autopsy 1–30–05. 10 am Severe local reaction hemorrhage –Skin bound down by plastic exudate. Edema marked, extending to neck. No fluid in pleuras. Peritoneum normal. Adrenals infected and swollen. E.I.

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 19 of 27

Harness and lead for the horse “First Flight” and a bottle of botulism antitoxin, 1970s

Courtesy National Museum of American History

The thoroughbred horse “First Flight” was used to produce serum for botulinum toxin, the deadly bacterial poison often spread through foods. He produced the antitoxin for the U.S. Army from 1978–1993.

-

MedlinePlus

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 20 of 27

A photo of Old Faithful in Who’s Who Among the Microbes by William H. Park and Anne W. Williams, 1929

Courtesy National Library of Medicine

“Old Faithful,” was a horse that produced antitoxins for the city of New York in the early twentieth century. A few of the individual horses used for serum production were celebrated for their service to humankind.

-

MedlinePlus

-

EnlargeImage

-

Copy Link

Copied

-

Injecting a horse with diphtheria toxin, New York City Health Department, 1940s

Courtesy Library of CongressLarge animals like horses were essential to produce the quantities of serum needed to supply the population.-

EnlargeImage

-

Copy Link

Copied

-

-

Bleeding a horse for antitoxin production, New York City Health Department, 1940s

Courtesy National Museum of American HistoryLarge animals like horses were essential to produce the quantities of serum needed to supply the population.-

EnlargeImage

-

Copy Link

Copied

-

-

Collecting blood from horses for antitoxin production, Parke, Davis & Company, ca. 1925

Courtesy National Museum of American HistoryLarge animals like horses were essential to produce the quantities of serum needed to supply the population.-

EnlargeImage

-

Copy Link

Copied

-

-

Injecting a horse with diphtheria toxin, Parke, Davis & Company, ca. 1925

Courtesy National Museum of American HistoryLarge animals like horses were essential to produce the quantities of serum needed to supply the population.-

EnlargeImage

-

Copy Link

Copied

-

Injecting a horse with diphtheria toxin, New York City Health Department, 1940s

Courtesy Library of Congress

Close Menu ITEM 22 of 27

Animal record book, New York City Department of Health, 1897–1898

Courtesy National Museum of American History

-

MedlinePlus

-

Transcript

Animal no. 1 Sex: Gelding Age: 9 years Color: Gray Purchased: October 24, 1894 Cost: $5.00 Final Disposition: Died Jan 6, 1899 Notes: Died from hepatic hemorrhages secondary to amyloid changes in liver Injection 1897: Nov. 2 Toxin Used: 175_1/300 Bleeding 1897: Nov. 18 Product No. of Flasks: 4 Product Quantity C.C.: 2700 Date 1897: Nov. 26 Forwarded No. of Bottles: 1 Forwarded Quantity C.C.: 850 Injection 1897: Nov. 2 Toxin Used: 175_1/300 Bleeding 1897: Nov. 18 Product No. of Flasks: 4 Product Quantity C.C.: 2700 Date 1897: Nov. 26 Forwarded No. of Bottles: 1 Forwarded Quantity C.C.: 600 Injection 1897: Nov. 2 Toxin Used: 175_1/300 Bleeding 1897: Nov. 18 Product No. of Flasks: 4 Product Quantity C.C.: 2700 Date 1897: Dec. 2 Forwarded No. of Bottles: 2 Forwarded Quantity C.C.: 1250 Injection 1897: Dec. 5 Toxin Used: 200_1/300 Bleeding 1897: Dec. 16 Product No. of Flasks: 4 Product Quantity C.C.: 3255 Date 1897: Dec. 23, 30 Forwarded No. of Bottles: 4 Forwarded Quantity C.C.: 3255 1898 Injection 1897: Jan. 6 Toxin Used: 500_1/125 Bleeding 1897: Jan. 19 Product No. of Flasks: 4 Product Quantity C.C.: 2745 Date 1897: Feb. 15 Forwarded No. of Bottles: 4 Forwarded Quantity C.C.: 2745 Injection 1897: Feb. 6 Toxin Used: 350_1/300 Bleeding 1897: Feb. 18 Product No. of Flasks: 4 Product Quantity C.C.: 3280 Date 1897: Mar. 9 Forwarded No. of Bottles: 4 Forwarded Quantity C.C.: 3280 Injection 1897: Feb. 6 Toxin Used: 350_1/300 Bleeding 1897: Mar. 2 Product No. of Flasks: 5 Product Quantity C.C.: 3535 Date 1897: Mar. 11 Forwarded No. of Bottles: 5 Forwarded Quantity C.C.: 3535 Injection 1897: Apr. 1 Toxin Used: 600_1/200 Bleeding 1897: Apr. 9 Product No. of Flasks: 3 Product Quantity C.C.: 2160 Date 1897: Apr. 11, May 25 Forwarded No. of Bottles: 3 Forwarded Quantity C.C.: 2160 Injection 1897: Apr. 1 Toxin Used: 600_1/200 Bleeding 1897: Apr. 19 Product No. of Flasks: 3 Product Quantity C.C.: 2330 Date 1897: May 13 Forwarded No. of Bottles: 3 Forwarded Quantity C.C.: 2330 Injection 1897: Apr. 1 Toxin Used: 600_1/200 Bleeding 1897: May 11 Product No. of Flasks: 4 Product Quantity C.C.: 3305 Date 1897: June 11 Forwarded No. of Bottles: 4 Forwarded Quantity C.C.: 3305 Injection 1897: Oct. 30 Toxin Used: 600_1/200 Bleeding 1897: Nov. 10 Product No. of Flasks: 2 Product Quantity C.C.: 895 Date 1897: Dec. 8 Forwarded No. of Bottles: 2 Forwarded Quantity C.C.: 895 Injection 1897: Nov. 13 Toxin Used: 700_1/200 Bleeding 1897: Nov. 23 Product No. of Flasks: 5 Product Quantity C.C.: 3570 Date 1897: Dec. 9 Forwarded No. of Bottles: 5 Forwarded Quantity C.C.: 3570 Injection 1897: Dec. 5 Toxin Used: 800_1/200 Bleeding 1897: Dec. 14 Product No. of Flasks: 4 Product Quantity C.C.: 2575 Date 1897: Jan 12, 17, 1899 Forwarded No. of Bottles: 4 Forwarded Quantity C.C.: 2575

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 23 of 27

How Did They Make Diphtheria Antitoxin?

-

MedlinePlus

-

EnlargeImage

-

Copy Link

Copied

Brewing Mysteries

Beer making is an old technology that relies on microorganisms. Brewers, however, barely knew of the existence of microbes, much less the critical role they played in their livelihood. Problems encountered in beer production, motivated scientists to study the secrets of this "invisible world."

In the mid—19th century, chemist Louis Pasteur worked with French beer makers to discover what was causing their product to spoil. Through his investigation into the "diseases" of beer, Pasteur demonstrated the essential role that yeast, a tiny living organism, played in the fermentation process and identified microorganisms that caused beer to go bad.

Breweries, as well as other fermentation based industries, adopted new scientific tools and techniques in order to better control the productive and destructive power of microorganisms.

Close Menu ITEM 1 of 20

Engraving of a beer vat designed by Louis Pasteur, ca. 1880

Courtesy National Library of Medicine

The closed fermentation tank prevented air–borne bacteria from entering and spoiling the brew.

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 2 of 20

“The Brewer,” engraving by Jost Amman, 16th century

Courtesy National Museum of American History

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 3 of 20

Drawings by Louis Pasteur of microscopic organisms, culturing vessels and equipment from his experiments, 1861

Courtesy Library of Congress

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 4 of 20

French chemist Louis Pasteur, 1889

Courtesy National Library of Medicine

Pasteur’s work is celebrated as laying the foundation for the science of bacteriology. His investigations on the behalf of French industry established tools and techniques necessary for controlling the productive and destructive power of microorganisms.

-

Transcript

Paris France March 1, 1887 This Filter was invented in my laboratory where its great usefulness is put to test every day. Knowing its full scientific and hygenic value, I wish it to bear my name. L. Pasteur.

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 5 of 20

Pasteur Chamberland filter, early 20th century

Courtesy National Museum of American History

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 6 of 20

“Section and elevation of Chamberland’s filter” from Microbes, Ferments and Moulds, Edouard Louis Trouessart, 1891

Courtesy National Library of Medicine

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 7 of 20

Pasteur flask, early 20th century and Microscope, made in France by Nachet et Fils, ca. 1860

Pasteur used special tools and methods for studying the activity of microorganisms in the brewing process. Flasks with long curved necks allowed oxygen to get in while keeping unwanted microbes out. Improvements in microscope lenses made the identification of different microorganisms possible.

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 8 of 20

Yeast, Études sur la Bière (Studies on Beer) by Louis Pasteur, 1876

Courtesy National Library of Medicine

An illustration in Pasteur’s book shows what healthy and worn–out yeast cells look like when viewed through the microscope.

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 9 of 20

Diagram and cross-section of beer vat, Études sur la Bière (Studies on Beer) by Louis Pasteur, 1876

Courtesy National Library of Medicine

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 10 of 20

Prepared culture tubes and sterile swab, Parke, Davis & Company, 1898

Courtesy National Museum of American History

These culture tubes were used to grow microbes for identification. They contain a special preparation of nutrients in a jelly–like base. A sterile instrument like the swab was used to transfer the test substance to the tube.

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 11 of 20

“Bacterium Acidi lactici,” Atlas of Bacteriology, 1897 Courtesy National Library of Medicine

Lactic–acid bacteria, a major cause of spoilage in the brewing process, are shown growing on a variety of culture media.

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 12 of 20

“Incubator,” from The American Handbook of the Brewing, Malting and Auxiliary Trades by Robert Wahl, PhD, and Max Henius, PhD, 1901

Courtesy National Museum of American History

Brewing handbooks described the tools and techniques needed for the study of yeasts and bacteria encountered in the brewing process.

-

EnlargeImage

-

Copy Link

Copied

-

Études sur la Bière (Studies on Beer) by Louis Pasteur, 1876

Courtesy National Library of MedicineThis illustration from Pasteur’s book demonstrates a method for examining the yeast in beer without exposing the sample to contamination from other microorganisms.-

EnlargeImage

-

Copy Link

Copied

-

-

Glass tube from Études sur la Bière (Studies on Beer) by Louis Pasteur, 1876

Courtesy National Library of MedicineThis glass tube has a flat circular lens in the middle. One end of the tube is connected to the flask neck with the tap, the flat lens is placed under the microscope, and the other end is connected to a rubber tube. The fermenting liquid pushed by the increasing air pressure in the flask travels into the glass tube onto the lens. The lens is air–tight, preventing any air contamination, and is thin enough to view the liquid inside with a microscope. The other end of the glass tube is connected to another rubber tube that drains the liquid into a glass (V).-

EnlargeImage

-

Copy Link

Copied

-

-

Flask from Études sur la Bière (Studies on Beer) by Louis Pasteur, 1876

Courtesy National Library of MedicineThe ball–shaped flask has two long necks. One bends to the side and bottom, and its end is placed in the mercury bowl (b). The other flask neck has a tap/faucet (r) connected to a long tube that runs inside of the neck and extends to the bottom of the flask. Liquid prepared for fermentation is placed in the flask.-

EnlargeImage

-

Copy Link

Copied

-

-

Bowl from Études sur la Bière (Studies on Beer) by Louis Pasteur, 1876

Courtesy National Library of MedicineA bowl contains mercury where the bent-neck end of the flask (A) is submerged. This setup minimizes the fermenting liquid in the flask from becoming contaminated by any microbes in the outside air.-

EnlargeImage

-

Copy Link

Copied

-

-

Tap/faucet from Études sur la Bière (Studies on Beer) by Louis Pasteur, 1876

Courtesy National Library of MedicineA tap/faucet is connected to the tube that runs inside of the flask neck to its bottom. When the liquid inside the flask ferments, it produces gases that increase pressure in the flask and push the liquid up the inner tube toward the connected tap/faucet. The open tap allows the liquid to flow into another glass tube with a flat lens (l-l) that sits under the microscope.-

EnlargeImage

-

Copy Link

Copied

-

-

Collecting glass from Études sur la Bière (Studies on Beer) by Louis Pasteur, 1876

Courtesy National Library of MedicineA glass collects the liquid draining from the side of the glass tube (l-l) away from the flask and microscope.-

EnlargeImage

-

Copy Link

Copied

-

Études sur la Bière (Studies on Beer)

Close Menu ITEM 19 of 20

Drawing of Yeast by Anton van Leeuwenhoek, 1680

Courtesy National Library of Medicine

Dutch lens maker Anton van Leeuwenhoek was probably the first person to see yeast. He made this drawing in 1680, after viewing beer through his primitive homemade microscope.

-

EnlargeImage

-

Copy Link

Copied

Close Menu ITEM 20 of 20

“How did they ferment beer?”

Created by Link Studio

-

Copy Link

Copied

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Egestas purus viverra accumsan in nisl. Vulputate dignissim suspendisse in est ante in nibh mauris cursus. Consectetur purus ut faucibus pulvinar elementum integer enim neque volutpat. Massa sapien faucibus et molestie ac feugiat sed lectus vestibulum. Id diam vel quam elementum pulvinar etiam. Tristique sollicitudin nibh sit amet commodo nulla facilisi. Odio euismod lacinia at quis risus sed vulputate odio.

-

DigitalCollections

-

Transcript

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

-

EnlargeImage

-

MedlinePlus

-

Copy Link